MFB Burner Aim Reducing Emissions l เครื่องพ่นไฟระบบมลพิษต่ำ

| รหัสสินค้า | MFB Low NOx |

| หมวดหมู่ | เบิร์นเนอร์แก๊ส - PYROPRECISION |

| ราคา | 0.00 บาท |

| สถานะสินค้า | พร้อมส่ง |

| ลงสินค้า | 3 มี.ค. 2567 |

| อัพเดทล่าสุด | 7 ต.ค. 2567 |

| คงเหลือ | ไม่จำกัด |

| จำนวน | ea |

หยิบลงตะกร้า

รายละเอียดสินค้า

MFB Burner Aim Reduce Emission l เครื่องพ่นไฟระบบมลพิษต่ำ (อยู่ระหว่างการพัฒนา)

PP Systems aims to accelerate emission reduction by developing a surface combustion gas burner that generates lower pollutants compared to conventional systems. By analyzing figures from the International Energy Agency, Carbon Brief predicts that global CO2 emissions could reach their peak this year.

PP Systems has taken the first step towards achieving their goal by commencing exploration of the PYROprecision burner's environmental performance. This data, including CO2, NOx, and CO levels, will be presented on the burner's data sheet.

The company's second step involves conducting research and development to enhance surface combustion technology. This advancement aims to meet global and industry standards and is essential for achieving their milestone objectives.

_______________________________________________________

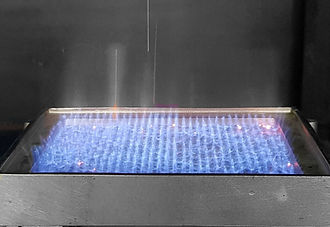

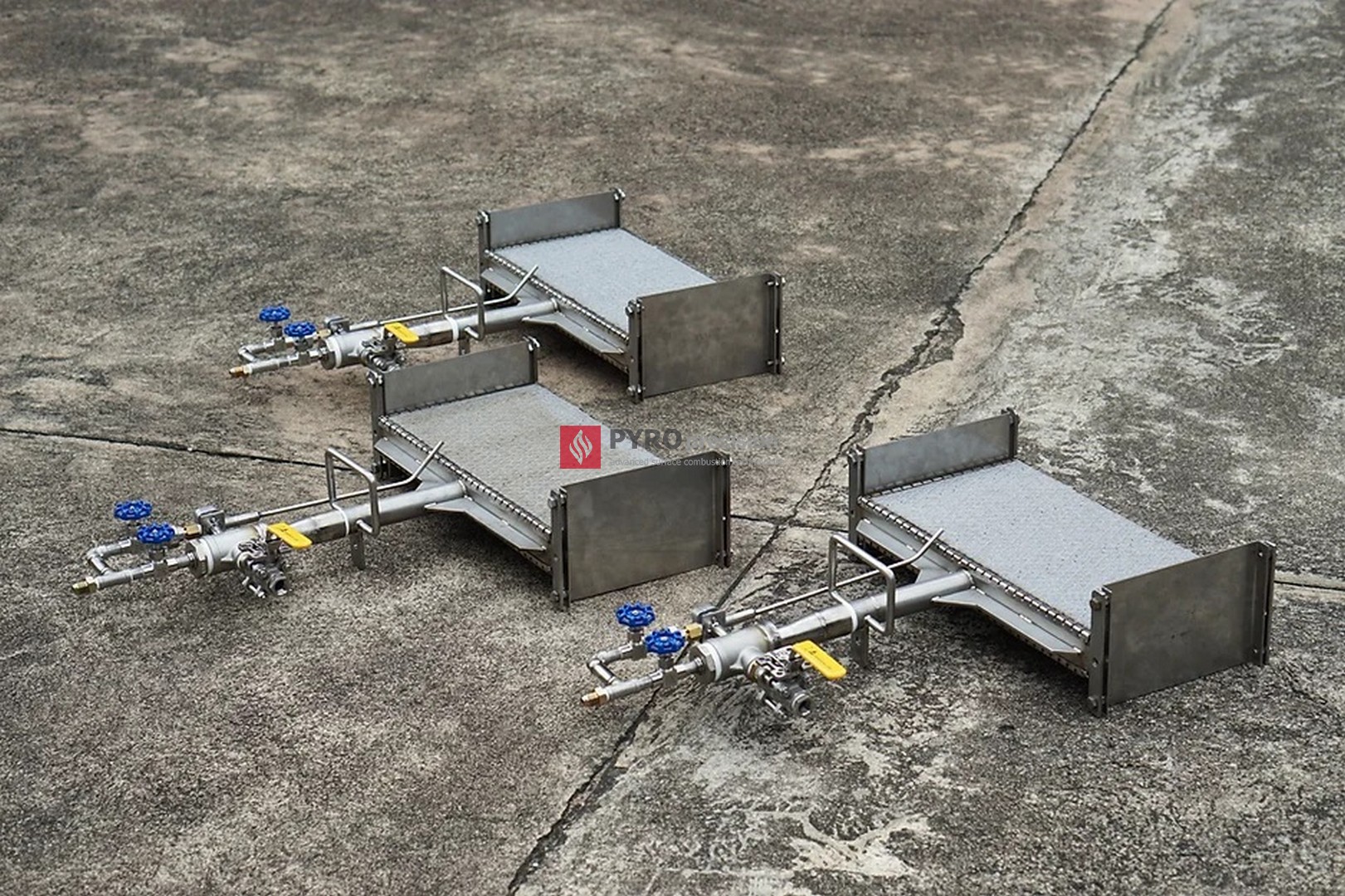

WHY METAL FIBER BURNER ?1. SUPERIOR MATERIAL - The key component build from metallic fibers made from extreamly high temperature resistance up to 1,100°C. It allows mixture gas and air combustion on its suface, produce uniform heat distribution with various flame structures. Our design can fabricate even flexible shape called woven and knitted media or solid sintered sheet meet PYRO Precision standard. Food grade, high corrosion resistance stainless steel 304 & 310 body and venturi mixer, using high accuracy equipments such as casting, CNC machine, bender, fiber laser cutting & welding.

2. ZERO MAINTANACE - Surface heating media can also withstand both mechanical and thermal shock resistance much better than fragile ceramic surface heating. All burner components has no moving part, service maintanance cost is relatively low.

3. BUILD SIMPLE "You may not need high experienced to install and operate PYRO Precision's gas burners." - All our design employed multi-stage venturi mixer (PP Systems' patent), its operation is very easy, just only supply correct gas pressure meet our instruction which can miximized power up to 80 kW.

4. LOW EQUIPMENT COST PER KILOWATT - Relatively high power, high turn-down ratio, simplify venturi design burner components and ignition system. MFB burner achieves the best price performance in equipment cost per maximum power compared to traditional venturi and package burner.

5. BETTER CONTROL ACCURACY - Wider operation range between maximum-minimum (turn-down ratio) offers varities control options such as on-off, high-low firing (two stage) and modulating gas (0-100%). Better control accuracy bring abount significant energy saving,

AX-Flow linear gas control valves have been introduced since early 2018 developed by PP Systems Co., Ltd. (Thailand). The products are supplied under trademark HEATwave. The AX-Flow control valves are our best solution for atmospheric venturi mixed gas burner can achieved :

2. ZERO MAINTANACE - Surface heating media can also withstand both mechanical and thermal shock resistance much better than fragile ceramic surface heating. All burner components has no moving part, service maintanance cost is relatively low.

3. BUILD SIMPLE "You may not need high experienced to install and operate PYRO Precision's gas burners." - All our design employed multi-stage venturi mixer (PP Systems' patent), its operation is very easy, just only supply correct gas pressure meet our instruction which can miximized power up to 80 kW.

4. LOW EQUIPMENT COST PER KILOWATT - Relatively high power, high turn-down ratio, simplify venturi design burner components and ignition system. MFB burner achieves the best price performance in equipment cost per maximum power compared to traditional venturi and package burner.

5. BETTER CONTROL ACCURACY - Wider operation range between maximum-minimum (turn-down ratio) offers varities control options such as on-off, high-low firing (two stage) and modulating gas (0-100%). Better control accuracy bring abount significant energy saving,

AX-Flow linear gas control valves have been introduced since early 2018 developed by PP Systems Co., Ltd. (Thailand). The products are supplied under trademark HEATwave. The AX-Flow control valves are our best solution for atmospheric venturi mixed gas burner can achieved :

- Better accuracy control

- Wider turndown ratio

- Less components

- No oscillation

- Easy to install

- Easy operating without professional control engineer.

_______________________________________________________

INDUSTRIAL APPLICATION

- Wider turndown ratio

- Less components

- No oscillation

- Easy to install

- Easy operating without professional control engineer.

_______________________________________________________

INDUSTRIAL APPLICATION

- Continuous and batch top grill process

- Induced draft circulation oven (-P)

- Forced draft space heating (+P)

- Rotary dryer - Coffee roaster

- Gravity casting preheat

- Road asphalt repair

- Laundry dryer

- High efficiency tank heating

- Underfire & small bore fired in tube

_______________________________________________________

ข้อมูลทางเทคนิค

A. Our metal fiber burner can be classfied by FIVE FLAME STRUCTURE accordingly :

B. Our metal fiber burner can be classified by shape and application by last burner part number accordingly :

_______________________________________________________

ดาวน์โหลด

แคตตาล๊อกสินค้า MFB Burner : Click Here

_______________________________________________________

หากต้องการข้อมูลเพิ่มเติม สอบถามปัญหาหรือสนใจในสินค้าของบริษัทฯ

สามารถติดต่อเราได้โดยตรงได้ทางช่องทางต่อไปนี้

- www.ppinfrared.com และ www.เตาอินฟาเรด.com

- pp@ppss.co.th

- LINE Official ID : @ppss

- คลิ๊ก http://line.me/ti/p/%40pff5148g

วิธีการชำระเงิน

ร้านค้านี้ยังไม่ได้กำหนดวิธีการชำระเงิน กรุณา ติดต่อกับทางร้าน เกี่ยวกับรายละเอียดในการชำระเงิน

ทางร้านยังไม่ได้ทำการเพิ่มบัญชีรับเงิน กรุณาติดต่อ เจ้าของร้าน

Recent

สถิติร้านค้า

| หน้าที่เข้าชม | 222,553 ครั้ง |

| ผู้ชมทั้งหมด | 119,915 ครั้ง |

| เปิดร้าน | 5 ม.ค. 2557 |

| ร้านค้าอัพเดท | 6 ธ.ค. 2568 |

ค้นหาสินค้า

ติดต่อเรา

หมวดหมู่สินค้า

ระบบสมาชิก

คุณเป็นตัวแทนจำหน่าย

- ระดับ{{userdata.dropship_level_name}}

- ไปหน้าหลักตัวแทน

ระดับสมาชิกของคุณ ที่ร้านค้านี้

รายการสั่งซื้อของฉัน

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน {{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- รอยืนยันได้รับสินค้า {{(order_nums && (order_nums.wait_receive || order_nums.wait_confirm))?'('+(order_nums.wait_receive+order_nums.wait_confirm)+')':''}}

- รอตรวจสอบข้อร้องเรียน {{(order_nums && order_nums.dispute)?'('+order_nums.dispute+')':''}}

- เรียบร้อยแล้ว {{(order_nums && order_nums.completed)?'('+order_nums.completed+')':''}}

- ทั้งหมด {{(order_nums && order_nums.all)?'('+order_nums.all+')':''}}

- รอการชำระเงิน {{(order_nums && order_nums.wait_payment)?'('+order_nums.wait_payment+')':''}}

- รอตรวจสอบยอดเงิน{{(order_nums && order_nums.wait_payment_verify)?'('+order_nums.wait_payment_verify+')':''}}

- รอจัดส่งสินค้า {{(order_nums && order_nums.wait_send)?'('+order_nums.wait_send+')':''}}

- ส่งสินค้าเรียบร้อยแล้ว {{(order_nums && order_nums.sent)?'('+order_nums.sent+')':''}}

PP Trade

PP Trade

{{is_joined?'เป็นสมาชิกแล้ว':'Join เป็นสมาชิกร้าน'}}

16

สมัครสมาชิกร้านนี้ เพื่อรับสิทธิพิเศษ

หน้าแรก | วิธีการสั่งซื้อสินค้า | แจ้งชำระเงิน | บทความ | เว็บบอร์ด | เกี่ยวกับเรา | ติดต่อเรา | ตะกร้าสินค้า | Site Map

ร้านค้าออนไลน์

Inspired by

LnwShop.com (v2)

▲

▼

รายการสั่งซื้อของฉัน

รายการสั่งซื้อของฉัน

ข้อมูลร้านค้านี้

PP Trade

ตัวแทนจำหน่ายสินค้าอุตสาหกรรม ได้รับความไว้วางใจ มากกว่า 35 ปี อุปกรณ์สำหรับระบบสีฝุ่นครบวงจร หัวเตาอินฟาเรด ระบบจุดสปาร์คแก๊ส-ควบคุมอุณหภูมิ ระบบให้ความร้อน ไฟฟ้า-แก๊ส สำหรับเตาอบอุตสาหกรรม ระบบหัวฉีดล้างชิ้นงาน ระบบพ่นหมอก เครื่องพ่นละอองฝอย เครื่องบันทึกอุณหภูมิ เครื่องดาต้าแพ็ค กล้องถ่ายภาพความร้อน (เทอร์โมสแกน) เครื่องวัดไข้

เบอร์โทร : 080 220 0005

อีเมล : pp@ppss.co.th

อีเมล : pp@ppss.co.th

ส่งข้อความติดต่อร้าน

เกี่ยวกับร้านค้านี้

ค้นหาสินค้าในร้านนี้

ค้นหาสินค้า

สินค้าที่ดูล่าสุด

บันทึกเป็นร้านโปรด

Join เป็นสมาชิกร้าน

แชร์หน้านี้

แชร์หน้านี้

↑

TOP เลื่อนขึ้นบนสุด

TOP เลื่อนขึ้นบนสุด

คุณมีสินค้า 0 ชิ้นในตะกร้า สั่งซื้อทันที

สินค้าในตะกร้า ({{total_num}} รายการ)

ขออภัย ขณะนี้ยังไม่มีสินค้าในตะกร้า

ราคาสินค้าทั้งหมด

฿ {{price_format(total_price)}}

- ฿ {{price_format(discount.price)}}

ราคาสินค้าทั้งหมด

{{total_quantity}} ชิ้น

฿ {{price_format(after_product_price)}}

ราคาไม่รวมค่าจัดส่ง

➜ เลือกซื้อสินค้าเพิ่ม